Finding the right solutions for safe and efficient medical device manufacturing is a key priority, but choosing the best equipment can often be another challenge. Dorner Conveyors offers a wide variety of solutions for medical device manufacturing to help your production process go as smoothly as possible.

Unique Challenges of Manufacturing Medical Devices

Medical devices are essential in healthcare, and safety is paramount as they make their way to patients. Manufacturing medical devices requires careful processes that ensure quality, safety, and compliance with medical standards.

To properly manufacture medical devices, you need to account for the following unique challenges:

Accuracy & Repeatability

Medical devices must be made to exact measurements and dimensions, and each device must be made in a uniform way. This can be immensely challenging, which is why medical manufacturing requires specialized equipment such as small conveyor systems that can maintain accuracy and repeatability as you scale production.

Quality Control

Manufacturing medical devices requires rigorous processes to ensure that each medical device meets stringent quality standards. Patients and healthcare providers must feel confident in the medical devices, which is why quality control is so vital.

However, maintaining quality control standards can often be tough if the manufacturing equipment used, including conveyors for medical device companies, is not up to the task. The quality and flexibility of your conveyors and other equipment can have a significant impact on the quality of your overall production.

Compliance With Regulatory Standards

Even the smallest of errors in the production process can lead to poor quality medical devices. When medical devices are not properly manufactured, they may not meet the standards of the industry, making them unsafe for distribution and use.

These errors can have severe consequences for medical device companies as well as patients, so selecting the right equipment and ensuring consistency and repeatability in quality during your manufacturing process is vital.

Sterility & Cleanliness

The healthcare sector, including medical device companies, is held to high standards of sterility and cleanliness during their manufacturing processes. For medical device companies, maintaining a sterile, clean environment for the production process requires a combination of having the right environment and tailored equipment to prevent contamination.

Flexibility

As the medical device industry evolves, flexibility is also needed to meet demand and development. Any equipment used in the manufacturing process needs to be adaptable to keep up with innovation and market changes.

Flexibility is not just limited to external market forces; it is also required for the medical equipment manufacturing process. As a company grows and scales production, it’s crucial to have pharmaceutical line conveyors and medical device conveyors that can accommodate any changing space limitations or needs.

Traceability

Maintaining traceability while still ensuring efficiency in manufacturing medical devices can be challenging, especially during peak production times. That is why each part of the production process must be accounted for, including the ability to trace individual parts as well as errors and contamination risks.

How Dorner Conveyors Can Help You Streamline the Medical Devices Manufacturing Process

Without the right equipment, overcoming the unique challenges of medical device manufacturing becomes even more difficult, which is why we offer custom, flexible conveyance solutions to meet your needs.

Dorner pharmaceutical line conveyors and medical device conveyors can be essential tools in streamlining your production process.

Custom Systems for Unique Problems

Medical equipment manufacturing requires tailored solutions that maintain quality standards and compliance with regulations. We can customize your conveyor system to suit your space, applications, and needs.

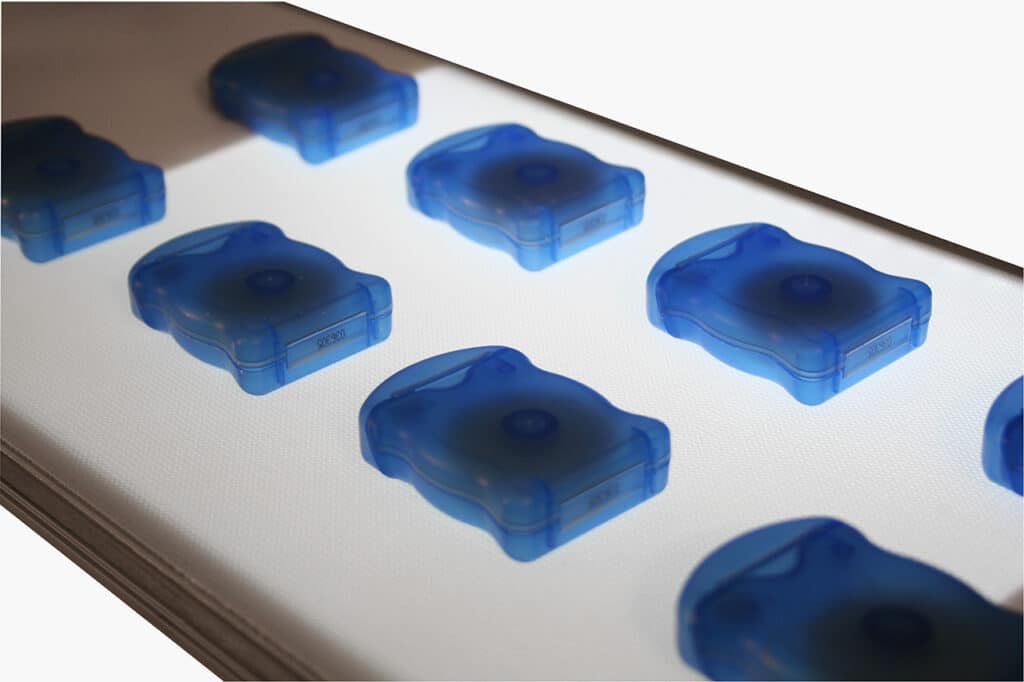

Dorner conveyors, such as the 2200 FlexMove Pallet System, can be engineered to fit unique systems, achieving the high rates of accuracy you need while following the specific processes you use to manufacture medical devices.

Sanitary Conveyors for Sterile Applications

The AquaGard series includes measures that make it easier to continually clean surfaces, monitor flagged products, and handle product removals. These conveyors are designed and manufactured for industries that require high levels of sanitation and include FDA-approved materials and components for enhanced product safety.

Miniature Conveyors for Precision Handling of Small Parts

Miniature conveyor systems can help maintain consistent precision and accuracy across the medical manufacturing process. The 1100 Miniature Conveyor is one of the smallest conveyors available in the industry and can precisely handle small parts and small parts transfers without compromising the medical device production process.

Improve Your Medical Device Manufacturing Process With Custom Conveyor Systems From Dorner

Medical device manufacturing requires a balance of flexible, adaptable equipment while keeping a close eye on each aspect of the production process. Dorner offers a variety of tailored solutions, such as pharmaceutical conveyors and medical device conveyors for medical device manufacturing.

Dorner’s conveyor solutions ensure that your medical device manufacturing process is designed to your needs. With Dorner custom conveyor systems, you can customize solutions to your unique processes while maintaining key quality control and regulatory standards for your medical device products.